In order to bring a product from design to its physical form requires high precision, speed and collaboration. SolidWorks Design Services provides the tools and expertise to automate this process with its advanced 3D modelling, simulation, and data management.

These services help companies to reduce costs, improve quality and innovate faster.

What Are SolidWorks Design Services?

SolidWorks design services are a combination of the effectiveness of SolidWorks CAD software and professional engineering solutions. These services can help your product manufacturing plant to make the best out of 3D modelling, simulation and documentation programs. All these features integrated will ensure that the end product design is accurate, manufacturable and efficient.

The service providers of SolidWorks usually customize their services according to the requirements of your project, like initial concept designing, engineering drawing or virtual checking. This flexibility makes the SolidWorks design services highly valuable for all forms of product-based businesses.

The Role of SolidWorks in Product Development

SolidWorks supports cross-disciplinary actions, which allows mechanical, electrical, and industrial engineers to collaborate in a unified platform. It minimizes communication problems and makes sure that each detail of the product is aligned with the requirements. By leveraging professional services, businesses can get advanced configuration, design automation and data management solutions.

Key Benefits of Using SolidWorks Design Services

There are multiple benefits of using SolidWorks design, some of them are discussed below.

Accelerated Time to Market

One of the most effective offerings of SolidWorks design is its ability to speed up the product development cycles. Digital prototyping through SolidWorks reduces the requirement for multiple physical prototypes, which helps to save time. Design iterations can be tested virtually, which allows for faster refinement of products.

Cost Efficiency

SolidWorks Design Services allows companies to cut down their expenses at numerous points of the product lifecycle. Advanced simulation options, such as stress analysis, motion studies, and thermal testing of the software, allow engineers to spot and solve possible problems before production starts. This minimizes material wastage, the reworking process and costly manufacturing mistakes.

Moreover, it is logical to outsource design services to SolidWorks professionals so that designs can be optimized within the boundary of manufacturability and cost-efficiency at the design stage itself.

Enhanced Product Quality

SolidWorks includes proficient analysis options like Computational Fluid Dynamics (CFD), Finite Element Analysis (FEA) and movement simulation. Such abilities also allow design teams to identify the shortcomings of the design and to rectify them. As a result, products are more productive, resistant, as well as of better quality.

Customization and Scalability

Design services using SolidWorks are very flexible to the needs of any organization. Services can be contracted accordingly, whether it is a startup that is getting its initial product ready or a large company that has a large product line to deal with.

Additional support includes on-demand design support, automation, product data management (PDM) integration, as well as complete workflow optimization.

Real-World Examples of Enhanced Product Development

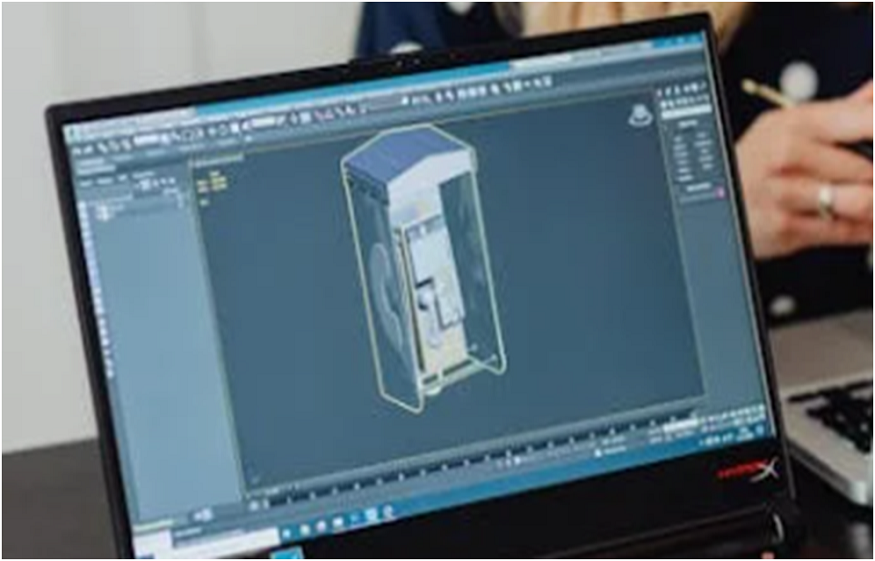

The SolidWorks Design Services have allowed many companies to get significant changes in their performance. For example, medical device manufacturing companies use SolidWorks to run designs and test custom prosthetics. Similarly, the consumer electronics industry uses its operations to advance surface software to design functional enclosures of electronic devices.

If an organization is building complicated parts or refining product aesthetics, SolidWorks Design Services can be used to create a quality product and achieve high efficiency in the marketing process.

The Future of SolidWorks Design Services

Along with the technological changes, such as the increasing tendency of generative design, artificial intelligence, and additive manufacturing (3D printing), SolidWorks Design Services is constantly developing. As the trend in CAD applications becomes cloud-based and integrated with the Internet of Things (IoT), SolidWorks is in a good place to serve the development of products of the next generation.

Furthermore, as sustainability is now a priority area, SolidWorks tools have made it possible to benefit the environment, material efficiency, and lifecycle assessment in terms of optimization by designers.

Conclusion

SolidWorks Design Services are the chance to get access to the hordes of powerful CAD software, but it is also a strategic advantage for companies that want to be the best in innovation, quality, and speed. These services allow companies to lower their expenditures, in addition to shortening development time and producing market-differentiating products through expert design assistance and cutting-edge modelling, simulation and data management technologies.